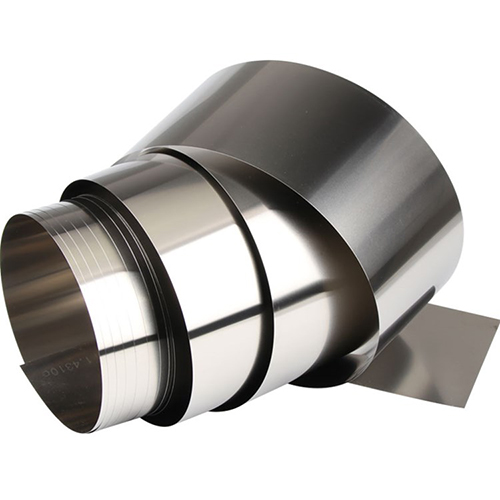

Titan zolagy we folga

• Titan zolagy we folga materiallary:Arassa Titan (CP) we Titan garyndy folga,1-nji synp, 2-nji synp, 5-nji synp, 5-nji synp, 7-nji synp we 9-njy synp

• Formalar: Bir zolak, rulonda ýa-da tabakda.Süýşmek hyzmaty elýeterli

Ölçegi:Galyňlygy: ≥0.01mm: 20 ~ 1000mm, Uzynlygy: Isleg boýunça

• itionsagdaýlar:Sowuk togalanan (Y) ~ Gyzgyn togalanan (R) ~ Annealed (M) ~ Gaty ýagdaý

• Standartlar:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 we ş.m.

• Goýmalar:Elektronika, himiýa, sagat, äýnek, şaý-sepler, sport harytlary, maşynlar, örtük enjamlary, daşky gurşaw enjamlary, golf we takyk işleýiş pudaklary.

| Titan erginleriniň umumy ady | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Titan zolagy we folga:Biz esasan Gr1, Gr2, Gr4 synplarynyň arassa titanium zolagyny üpjün edýäris;Titan garyndysy folga üçin, esasan Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 we beýleki derejeleri üpjün edýäris, titan plastinkasy esasynda has sowuk rulon bilen öndürilýär;titanium listini öndürmek has çylşyrymly.Deformasiýa gözegçiligi togalanmak prosesinde has berkdir. Müşderiniň isleglerine görä dürli ululykda kesilip bilner, gowşuryş wagtyny ep-esli gysgaldyp biler.

♦ Titan zolagy Himiki düzümi ♦

| Baha | Himiki düzümi, agram göterimi (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Beýleki elementler Maks.hersi | Beýleki elementler Maks.jemi | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum garyndy zolagyFiziki aýratynlyklar ♦

| Baha | Fiziki aýratynlyklary | |||||||

| Dartyş güýji Min | Hasyl beriňMin (0,2%, ofset) | 4D-de uzalma Min (%) | Meýdany azaltmak Min (%) | Bend synagy (Mandreliň radiusy) | ||||

| ksi | MPa | ksi | MPa | < 1.8mm Galyňlykda | Galyňlygy 1.8-4.8mm | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Titan garyndy materiallarynyň aýratynlyklary: ♦ ♦ ♦

•1-nji synp: Arassa titanium, deňeşdirilende pes güýç we ýokary süýümlilik.

•2-nji synp: Iň köp ulanylýan arassa titanium.Güýçleriň iň gowy utgaşmasy

•3-nji synp: Gabykda we turba ýylylyk çalşyjylarynda Matrix-plitalar üçin ulanylýan ýokary güýçli titanium

•5-nji synp: Iň köp öndürilen titanium garyndysy.Gaty ýokary güýç.ýokary ýylylyga garşylyk.

•7-nji synp: Daşky gurşawy azaltmakda we oksidlemekde ýokary poslama garşylyk.

•9-njy synp: Örän ýokary güýç we poslama garşylyk.

•12-nji synp: Arassa titandan has gowy ýylylyga garşylyk.7-nji synp we 11-nji synp üçin arzalar.

•23-nji synp: Titan-6Aluminum-4Wanadium ELI (Goşmaça pes interstisial) hirurgiki implant amaly üçin garyndy.